Symposium

Engineering in Practice Fontys Eindhoven

Report of Engineering in Practice Symposium at Fontys January 31 2018.

The symposium was organized by the Centre of expertise High Tech Systems and Materials (HTSM) and the school of engineering. This was the first event organized in this way. Important elements are the keynote (by Rick Wielens) and the project market with 30 projects (with each around 8 students). Each project showed results and took part in the competition for the two HTSM awards of 300 Euro each. One winner was chosen by the public and the other by the HTSM jury.

In parallel five teams were nominated for the KIVI award. The members of the KIVI jury reviewed the project reports and attended the project presentation in the morning to get an in-depth view on the projects. After careful discussion one project earned the KIVI award.

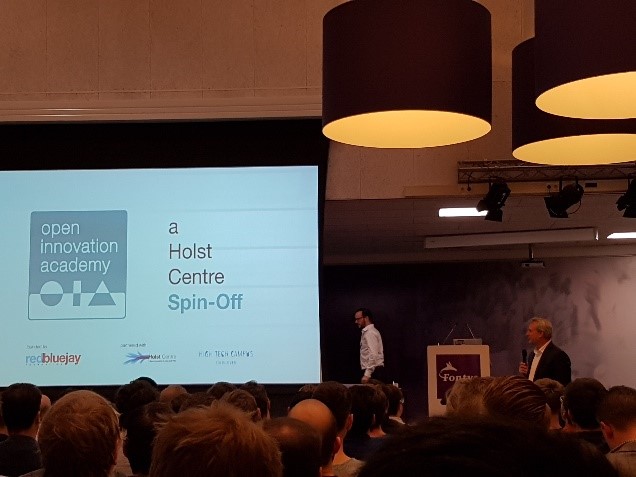

Keynote by Rick Wielens (LED Skin, Open Innovation Academy)

Rick shared his firsthand experience in user led innovation and open innovation; the new normal for the way innovation is done in companies today. With 10 years in the open innovation industry and 400+ innovation projects there were many good and bad examples.

Most of the corporates and organizations today are aware that innovation is about access and collaboration, not ownership. There is a clear business case for recycling the abundance of technologies and outcomes of user and market experiments from adjacent industries.

Wielens explains the link of the Academy to Holst Centre

KIVI award nomination: five projects were nominated:

- 3D orthopedic cast. Options are explored, and procedures defined for application of 3D print cast in hospitals. Should be cheaper, easier to apply and more comfortable for the patient. A collaboration with Wageningen University (WUR).

- PCB drilling Machine Design and construction of a PCB Drilling machine for the Fontys Electro Mechanical Manufacturing (FEMM) line. Precise movement of the drill should allow for automated drilling of the PCB holes with an accuracy of 5 um.

- Autonomous Package Transport Robot Design and build prototype of an autonomous parcel sorting robot. Should allow for a flexible setup of the sorting system. Cooperation with van der Lande.

- Lead frame cassette transport robot explore options for a transport robot and design prototype system for use in the assembly lines of Nexperia in Nijmegen.

- Validation of UWB sensor/actuator specs Validate properties of Ultra-Wide Band (UWB) communication with experiments to explore the options for application of those sensors by Fontys.

KIVI AWARD WINNER:

After a difficult deliberation on the projects, their report, the presentation of the team and the Q&A after the presentation the jury decided that the KIVI AWARD is for the team working on Lead frame Cassette Transport Robot.

Congratulations for the team!!

Presentation on the Lead frame cassette Robot

Lead frame team gets the “nomination certificate”

"Team with mentor after reception of the KIVI-award"

HTSM jury award

The project Shoe times was awarded with the first price. The project designed sensors in the shoe to prevent wounds created by friction of the foot with the sole of the shoe by optimizing the shape.

HTSM public award

The first price was awarded to the project which designed technology to create water in dry areas to enhance vegetation.

Zie verder:

Nieuwsbericht Fontys Engineering in Practice op 02 februari 2018

Programma |

|

|---|---|

| - uur | Ontvangst en registratie |

| - uur | Opening en welkom |

| - uur | Keynote speaker |

| - uur | Studentenpitches: meer dan 30 studentengroepen presenteren met een video hun project |

| - uur | Interactieve presentaties door bedrijven en Fontys* |

| - uur | Projectenmarkt |

| - uur | nteractieve presentaties door bedrijven en Fontys* |

| - uur | Uitreiking KIVI award & HTSM-awards |

| - uur | Netwerken met drinks |